From reactive to proactive

In the realm of industrial and manufacturing operations, the approach to maintenance can define the thin line between success and setback. Traditionally, many organizations have relied on a reactive maintenance strategy – fixing what breaks when it breaks. However, this approach is akin to navigating without a compass; you’re always a step behind. The advent of Computerized Maintenance Management Systems (CMMS) has ushered in a transformative shift from reactive to proactive maintenance. This blog explores how CMMS facilitates this cultural shift, leading to a more reliable and efficient operational environment, and offers tips for fostering a proactive maintenance culture within an organization.

Understanding the Shift

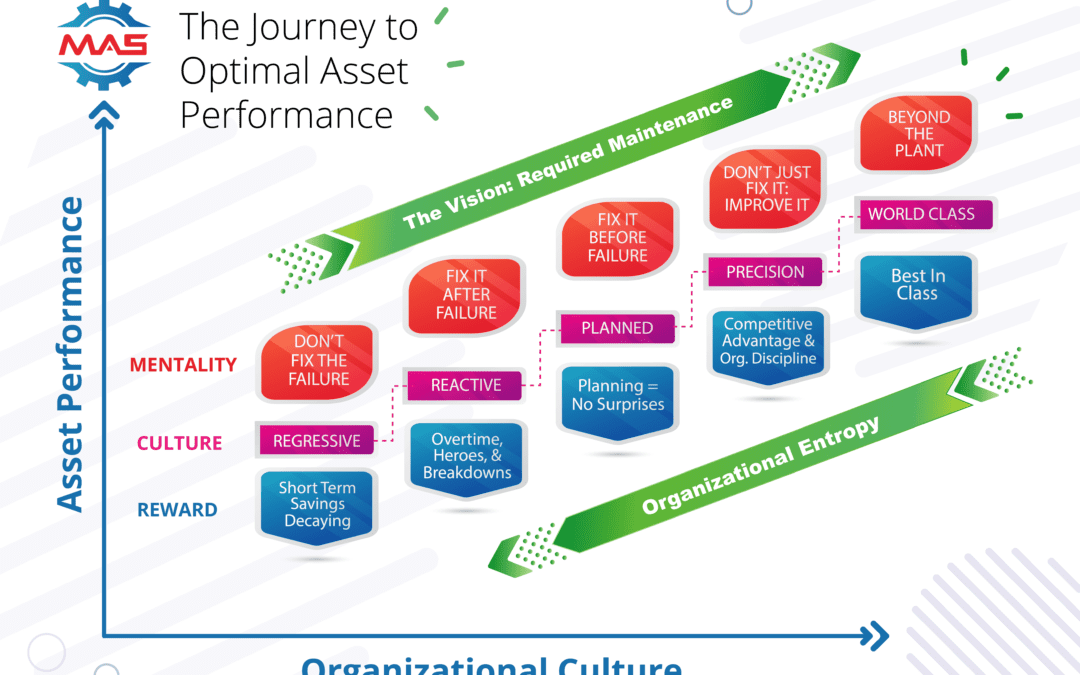

Reactive Maintenance: Characterized by a ‘wait until it breaks’ philosophy, reactive maintenance often results in increased downtime, higher repair costs, and disrupted production schedules. While it might seem cost-effective in the short term, the long-term implications are usually detrimental to both efficiency and finances.

Proactive Maintenance: In contrast, proactive maintenance, enabled and streamlined by CMMS, focuses on preventing breakdowns before they occur. It involves regular inspections, scheduled servicing, and predictive maintenance strategies. This approach not only minimizes downtime but also extends the lifespan of equipment, resulting in substantial cost savings and operational efficiency.

Role of CMMS in Cultivating a Proactive Culture

Predictive Maintenance Analytics: CMMS provides predictive analytics by monitoring equipment performance and predicting potential failures. This allows for maintenance to be scheduled at convenient times, avoiding the disruption of unexpected breakdowns.

Automated Maintenance Schedules: CMMS automates the scheduling of maintenance tasks, ensuring regular and timely attention to equipment. This automation helps in evenly distributing maintenance workload and prevents oversight of crucial maintenance activities.

Comprehensive Asset Management: CMMS offers a comprehensive view of each asset’s maintenance history, performance metrics, and servicing schedules, which aids in making informed decisions about maintenance and asset management.

Enhanced Communication and Documentation: With CMMS, maintenance teams can easily access and update maintenance records, fostering better communication and accountability. This shared information pool is critical for a proactive maintenance culture.

Tips for Encouraging a Proactive Maintenance Culture

Training and Education: Provide training for your team on the benefits of proactive maintenance and how to effectively use CMMS. Understanding the ‘why’ behind the change is crucial for team buy-in.

Set Clear Goals and KPIs: Establish clear maintenance goals and key performance indicators (KPIs) that align with proactive maintenance principles. Monitor these KPIs through CMMS to track progress and improvement.

Involve All Levels of Staff: Encourage a company-wide ethos that values regular maintenance. From the shop floor to the top management, everyone should understand their role in maintaining equipment health.

Regular Feedback and Continuous Improvement: Use feedback from the maintenance team to continually refine and improve maintenance processes. CMMS can aid in gathering and analyzing this feedback effectively.

Celebrate Successes: Acknowledge and celebrate when proactive maintenance strategies lead to improved outcomes. This recognition can reinforce the cultural shift and motivate the team.

Conclusion

The transition from a reactive to a proactive maintenance culture, facilitated by CMMS, is more than just a change in operations; it’s a change in mindset. By embracing this shift, organizations can achieve a more reliable, efficient, and cost-effective operational environment. Implementing CMMS is a crucial step in this transformative journey, offering the tools and insights needed to make proactive maintenance a tangible reality.

To discover more about how CMMS can revolutionize your maintenance strategy and help you shift towards a proactive culture, visit Express Maintenance for further insights and expert guidance.